All most people want to know about refrigeration is if it will keep their food cold. Even in the world of foodservice, few operators will interrupt the daily flow of business to consider how their food is being kept cold. They may be unaware that the type of refrigerants coursing through the pipes and compressors of their refrigerators are at a crossroads.

Sustainability and environmental responsibility touch every facet of our lives. And, the refrigeration industry is not immune to these realities — particularly when we talk about hydrofluorocarbons (HCFs), hydrochlorofluorocarbons (HCFCs) and hydrofluoroolefins (HFOs). It is acknowledged that synthetic HCF- and HCFC-based refrigerants play a significant role in climate change and ozone layer damage, while HFO-based refrigerants are detrimental to other areas of the environment. In response, national regulators and international coalitions have created ambitious regulations taking aim at the environmental impact of refrigerant gasses.

Consequently, there is an imperative to find a better way to keep our refrigeration running.

Among the solutions stands R-290 — commonly known as propane — an efficient and eco-friendly refrigerant gas. The favorable thermodynamic and transport properties of propane mean it reduces refrigerant costs as well as energy consumption. Because R-290 is a natural resource, it is well suited for protecting the air quality and the stratospheric ozone layer in ways its predecessors never could.

We’ll explore everything you need to know about R-290. Our aim is to help you understand the trade-offs and balance to strike between product safety, environmental impact, performance and operators’ bottom lines. Keep reading to discover why R-290 has such a viable future. With a firmer understanding of the refrigerant landscape, you will have the confidence to provide clarity when it comes time for clients to make informed decisions.

Table of Contents

- Cool change – An introduction to basic refrigerant properties

- Freeze frame – An environmental picture of R-290

- Keeping it cool – The economical impact of R-290 on a business

- Frost forward – The regulatory landscape and what it means to operators

- Cool runnings – Refrigeration solutions utilizing R-290

- The coolest innovation – How businesses are adapting to R-290

- Breezing into the future – R-290 is ready for you

Cool change

An introduction to basic refrigerant properties

Out with the old, in with the … old.

Many operators are surprised to learn that the use of propane and other hydrocarbon refrigerants is not a new phenomenon. R-290 is a natural class A3 refrigerant that dates back to the earliest refrigeration compressors, over a century ago.

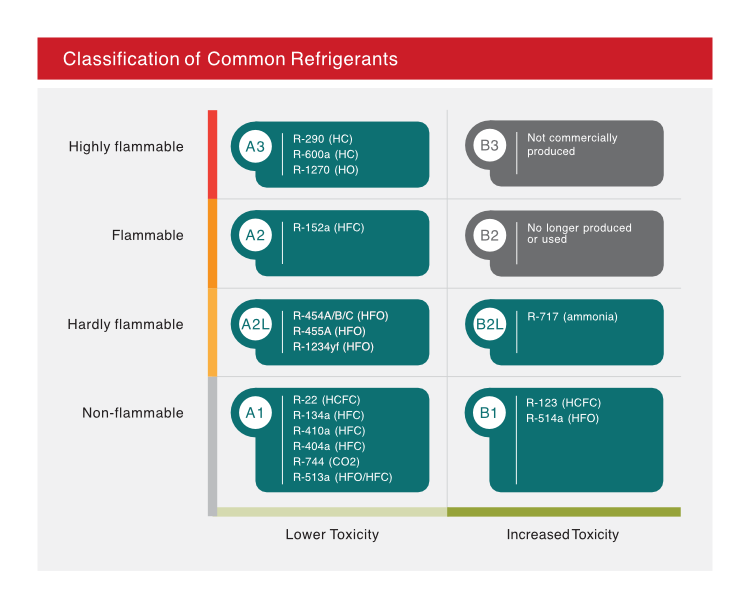

Class A3 refrigerants are categorized by their high flammability and low toxicity. However, at the time, the risks associated with flammability in system design, installation and maintenance of the refrigerant weren’t fully understood (and therefore largely inflated to be more scary than they really are).

Still, this worry led to the development of synthetic refrigerants that weren’t flammable. And, as long as synthetic refrigerants were low in immediate toxicity — through direct skin contact or inhalation — they became preferable to more flammable refrigerants.

This chart offers a visual representation of the flammability versus toxicity in various common refrigerants. This is not a complete list of refrigerant examples, but it includes many of the most common types.

What refrigeration engineers didn’t know for several decades was that toxicity and flammability only told part of the refrigerant story.

Until the mid-1980s, refrigeration engineers would read this chart and decide upon the least flammable refrigerant. Eventually, the International Electrotechnical Commission (IEC) set standards such as IEC 60335-2-89, which specify safety requirements for refrigeration appliances using flammable refrigerants. This significantly reduced the stigma and risk of using a flammable refrigerant. Furthermore, as the environmental impact of using synthetic refrigerants became greater understood (more on that in a moment), that same refrigeration engineer would really see this chart as more of a design catch-22.

Thanks to standards that greatly reduced the risk of flammability and a newfound eco-awakening, the stage was officially set for refrigerants like R-290 to make a comeback.

Freeze frame

An environmental picture of R-290

When scientists refer to HFC- and HCFC-based refrigerants as a “nightmare for the climate,” they are not exaggerating. The sky is falling — or at least getting a big hole in it.

As we’ll see, R-290 is a refrigerant unparalleled in its eco-friendliness. R-290 has almost no greenhouse effect and doesn’t harm the ozone layer.

Scientists use two scales when deciding the long-term negative effects a substance can have on the planet’s atmosphere.

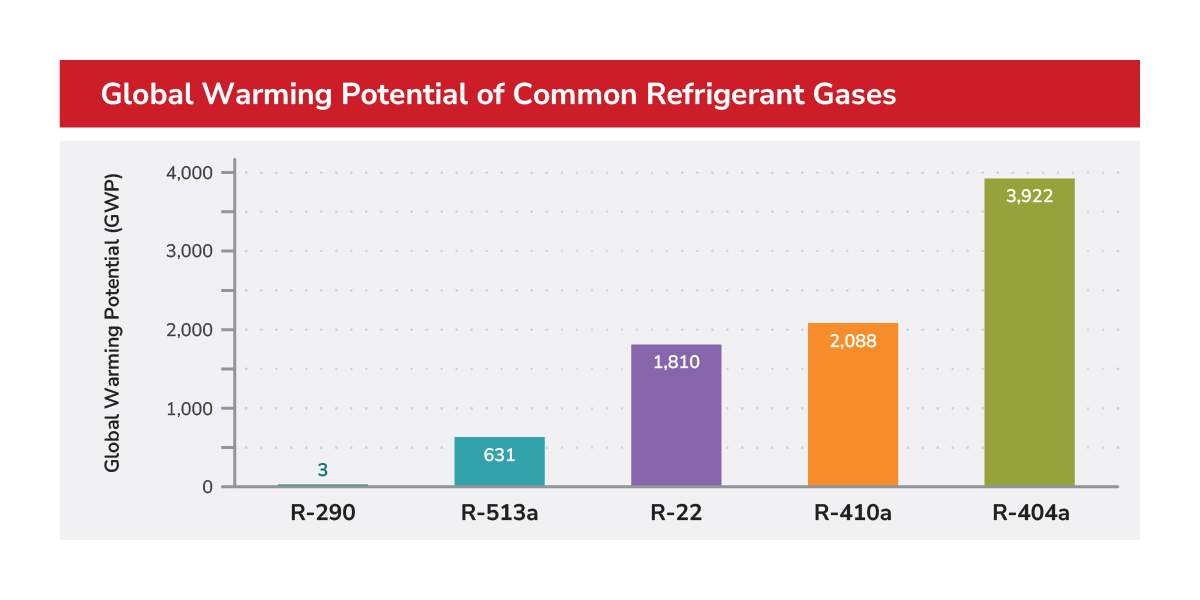

The first benchmark is Global Warming Potential (GWP), which determines the magnitude of a greenhouse gas. The GWP of a gas refers to the total contribution to global warming resulting from the emission of one unit of that gas relative to one unit of the reference gas, carbon dioxide (CO2) — which is assigned a value of one.

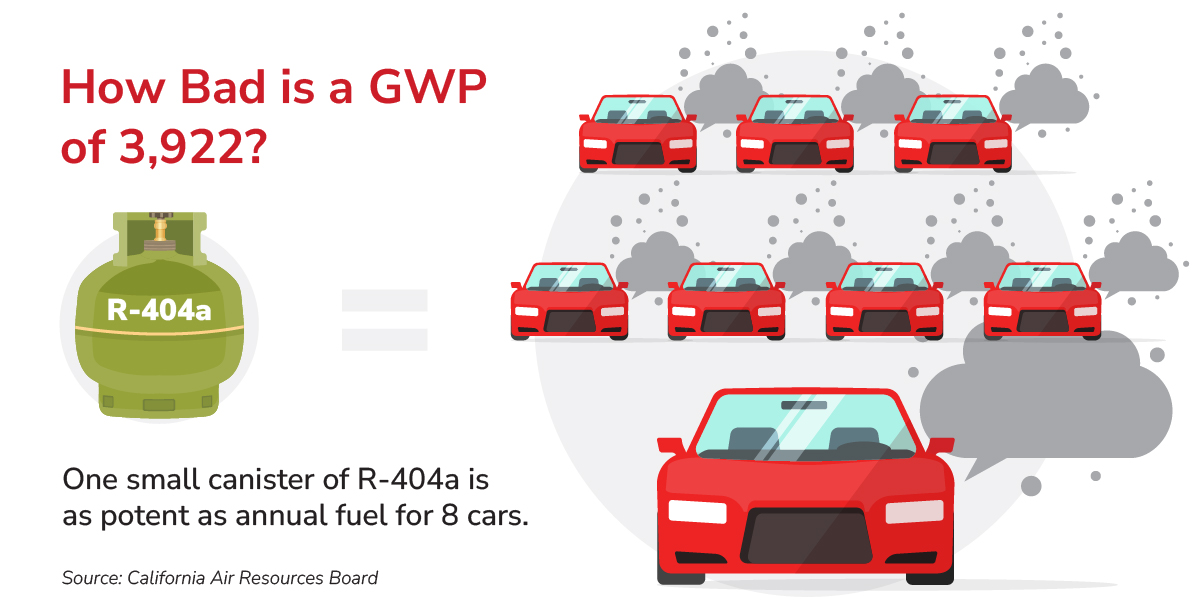

The lower the rating, the less that a gas is responsible for trapping the sun’s warmth in a “greenhouse.” R-290 has a GWP of 3, which is a negligible amount. A single pound of R-404a on the other hand, registers a GWP of 3,922, the equivalent of 2 tons of CO2. R-404a exemplifies how a refrigerant can, at first, appear to be ideal — low in toxicity and flammability. But, the full story reveals R-404a to be an outsized contributor to global warming.

The second scale is Ozone Depleting Potential (ODP), a metric to determine how much a substance destroys atmospheric ozone — the good kind of ozone — which is necessary for filtering out harmful ultraviolet (UV) light.

Incredibly, R-290 has an ODP of 0, which means it has zero culpability in destroying the ozone layer.

Keeping it cool

The economical impact of R-290 on a business

It’s time for a bit of background on R-290 thermodynamic basics. In short: It’s a science that is saving businesses money.

Economic performance begins and ends with energy efficiency. In the most technical terms, R-290 is an excellent heat transfer medium due to its high latent heat of vaporization. To decode the refrigeration engineer-speak into something everyone understands: R-290 has excellent thermodynamic properties — highly efficient cooling and lower energy consumption.

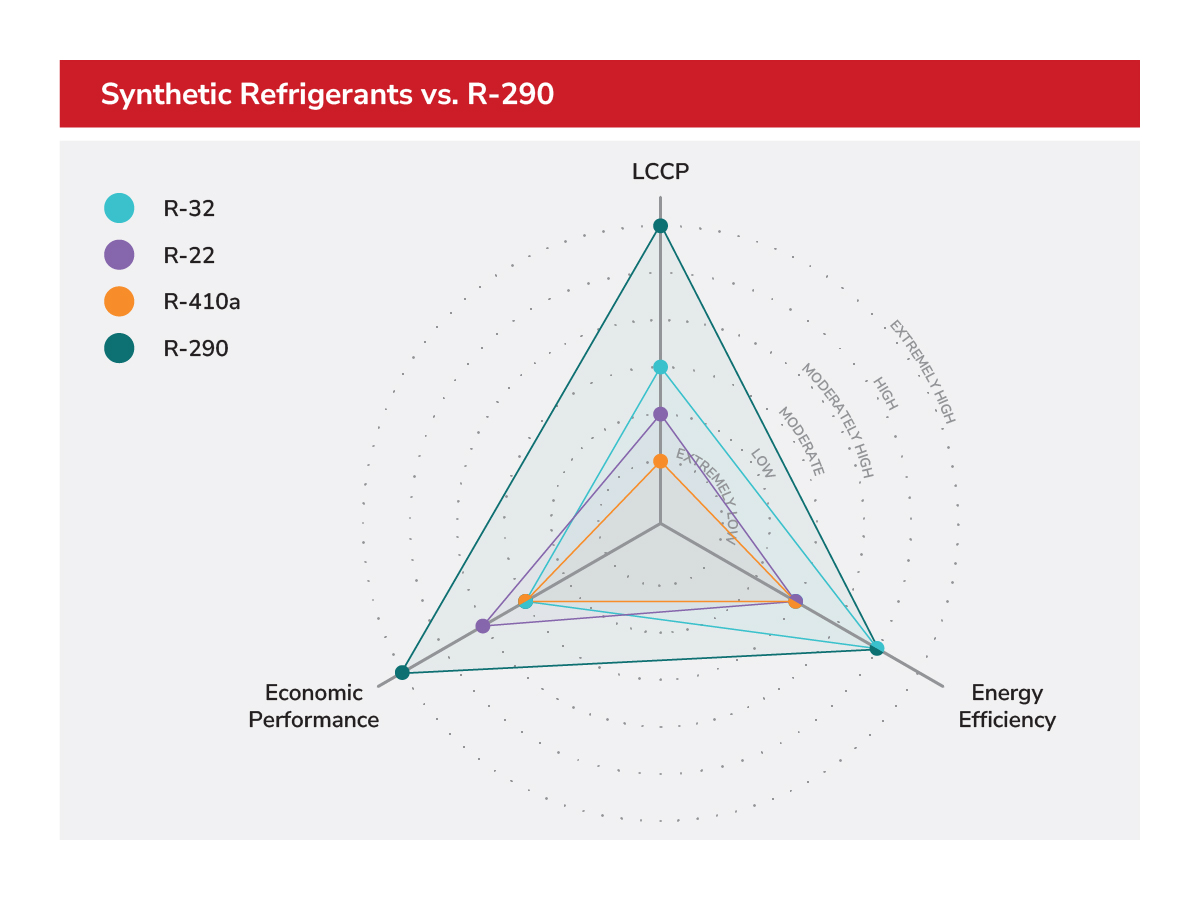

To gain a holistic evaluation of a refrigerant’s direct energy usage and indirect global warming impact, scientists developed the concept of Lifetime Cycle Climate Performance (LCCP). Think of LCCP as a refrigerant’s comprehensive environmental score. The higher the score, the better off the refrigerant is for the environment.

LCCP is an important indicator of all the ecological costs involved with a specific refrigerant over its lifetime. Amongst the pieces of data used to calculate LCCP are leakage and energy consumption, both of which directly lead to costs for businesses. Refrigerant leakage means costly service technician calls. And, of course, any reduction in the energy bill is a win.

More than 40 scientists from 24 different European nations corroborate these findings. They have signed a position statement backing what they say is the proven superior efficiency of hydrocarbon refrigerants.

Frost forward

The regulatory landscape and what it means to operators

The switch to natural refrigerants like R-290 isn’t just an ecological choice. By international mandate, it’s inevitably going to become the norm.

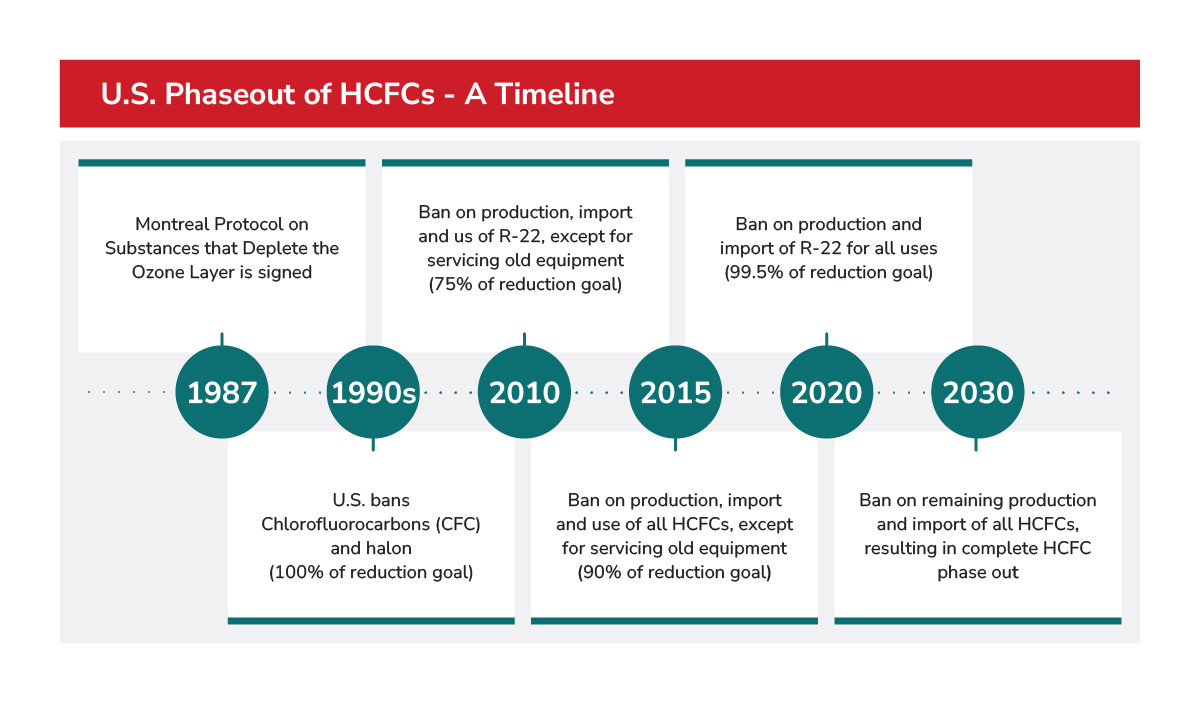

The ozone is vital in protecting the Earth from the sun’s most harmful ultraviolet rays. Unbeknownst for decades, the widespread use of synthetic refrigerants was causing a hole to form in the Earth’s stratospheric ozone layer. To make up for lost time, the United Nations (UN) came together in 1987 to adapt The Montreal Protocol on Substances that Deplete the Ozone Layer.

This was a landmark environmental agreement between nearly 200 countries with the express purpose of regulating the production and consumption of nearly 100 chemicals referred to as ozone-depleting substances (ODS).

Member nations have committed to a collaborative international effort to end the use of ozone-depleting substances. Timetables vary from country to country; the United States is looking for a complete phaseout by 2030. In summary, the writing is on the wall for synthetic refrigerants.

Cool runnings

Refrigeration solutions utilizing R-290

Following the negative impacts of synthetic refrigerants, new sources of refrigerant were waiting to emerge. R-290 is the frontrunner to fill that void.

Hatco has a long track record of being among the first to adapt to changes in the foodservice equipment industry. The first product we ever produced, the Electric Booster Water Heater, was created in response to midcentury health code changes. We see the R-290 refrigerant adaptation as next in a long line of advances that satisfies a moral imperative while creating innovations for businesses.

Once again, Hatco showcases its commitment to innovation — not to mention the climate — in refrigeration equipment cooled by R-290. This is foodservice equipment that will save operations money now and put them in a position to be in compliance down the road.

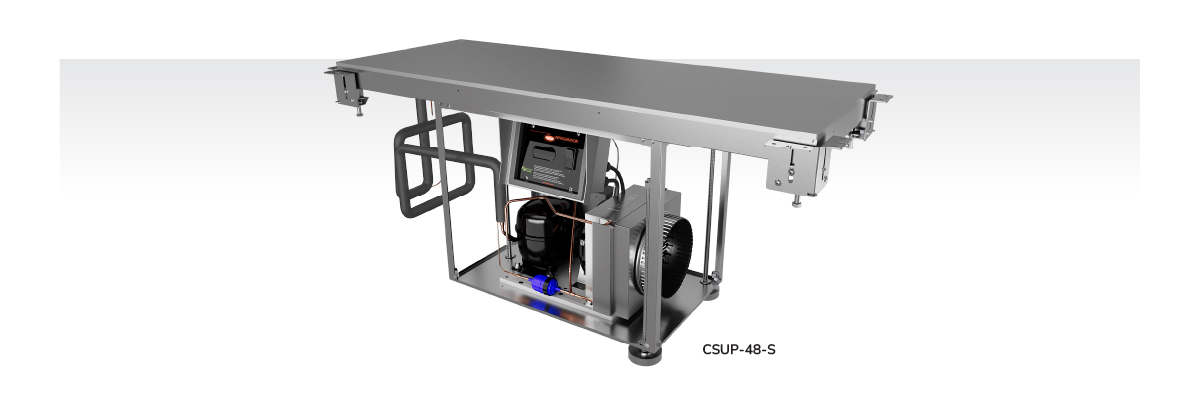

- Cold Undermount Shelf: This is the secret workhorse below many chilled food buffets. The aluminum surface is designed to be mounted directly against the underside of a granite or quartz countertop, which means cooling transfers through the countertop to the top side for a truly seamless experience.

- Cold Built-In Flush Top Simulated Stone Shelf and Cold Built-In Flush Top Shelf: These are aesthetically pleasing food-safe shelves designed to keep pre-chilled food products in the perfect chill zone for serving. The Cold Built-In Flush Top Simulated Stone Shelves are available in three beautiful stone colors — Night Sky (standard), Gray Granite and Bermuda Sand — to match any décor.

- Refrigerated Drop-In Well and Refrigerated Slim Drop-In Well: These full-size wells blanket pre-chilled food products to retain optimum freshness and taste. Optimal, eco-friendly spray foam insulation expands within the sides and bottom, ensuring even chilling from top to bottom for improved cold retention and cost savings.

- Drop-In Frost Top and Drop-In Slim Frost Top: These are specially designed frost tops to safely hold quick-turnaround, pre-chilled food products — beverages, snacks, hors d’oeuvres, side dishes, desserts — at optimum serving temperatures.

The coolest innovation

How businesses are adapting to R-290

Here’s what adapting to R-290 means. For starters, R-290 compressors require more cool air than their predecessors. Operators can rest assured that foodservice refrigeration equipment using R-290 will have the same footprint in an operation as older versions. The difference is that R-290 needs a 12 by 12 inch (305 by 305 mm) intake and exhaust vent. Hatco makes this conversion easy by including a 240-inch (6096 mm) expandable air conduit with all R-290 products to facilitate correct installation.

Many operators are completely unaware that R-290 use has been quietly increasing in commercial refrigeration over the last few years. Those who have embraced it are already seeing additional benefits. R-290 works better in hot climates than synthetic refrigerants. R-290 is also proving to be much more responsive and efficient than synthetic refrigerants.

R-290 has a wide range of applications. It has shown to be especially adept for scaling up refrigeration operations, from commercial to industrial. R-290 has good compatibility with other components. First of all, R-290 is chemically inert which means it does not react with other materials, thus preventing system degradation. Secondly, R-290 possesses high thermodynamic qualities similar to the most popular synthetic refrigerants, ensuring a smooth transition of refrigerant type.

R-290 is undeniably a long-term environmentally friendly refrigerant alternative. Operators can expect lower electricity bills and reduced environmental impact. R-290 units are 15% more energy efficient versus other conventional HFC systems. By lowering energy consumption and reducing operating costs, R-290 units have lower operating pressure and fewer mechanical parts which leads directly to improved durability and reliability.

On top of all that, R-290 is readily available, cost-effective and easily recyclable, further contributing to its appeal as a sustainable refrigerant.

Breezing into the Future

R-290 is ready for you

Refrigerants are one of the main contributors to global warming — and potentially part of the solution.

The switch to R-290 not only offers a more environmentally friendly refrigerant solution, but also a more efficient one. Operators can rest easy knowing that their foodservice equipment will meet upcoming regulatory requirements while benefiting from improved performance.

Are you ready for R-290? If so, Hatco is ready to help by providing a way to more sustainable, eco-friendly refrigeration. Contact us today to learn more.