The dramatic rise in to-go is no longer just a pandemic-era trend. Even with dine-in services rolling at full steam, pickup and delivery remain a constant go-to for just about every foodservice type in the industry. In fact, a recent Hatco survey unlocked some interesting insights that reveal how foodservice equipment buyers are feeling about to-go, and what kind of questions are on their minds. Let’s dig into the high-level survey findings and explore the top 10 to-go questions asked today.

Survey says: Buyers have to-go on the mind

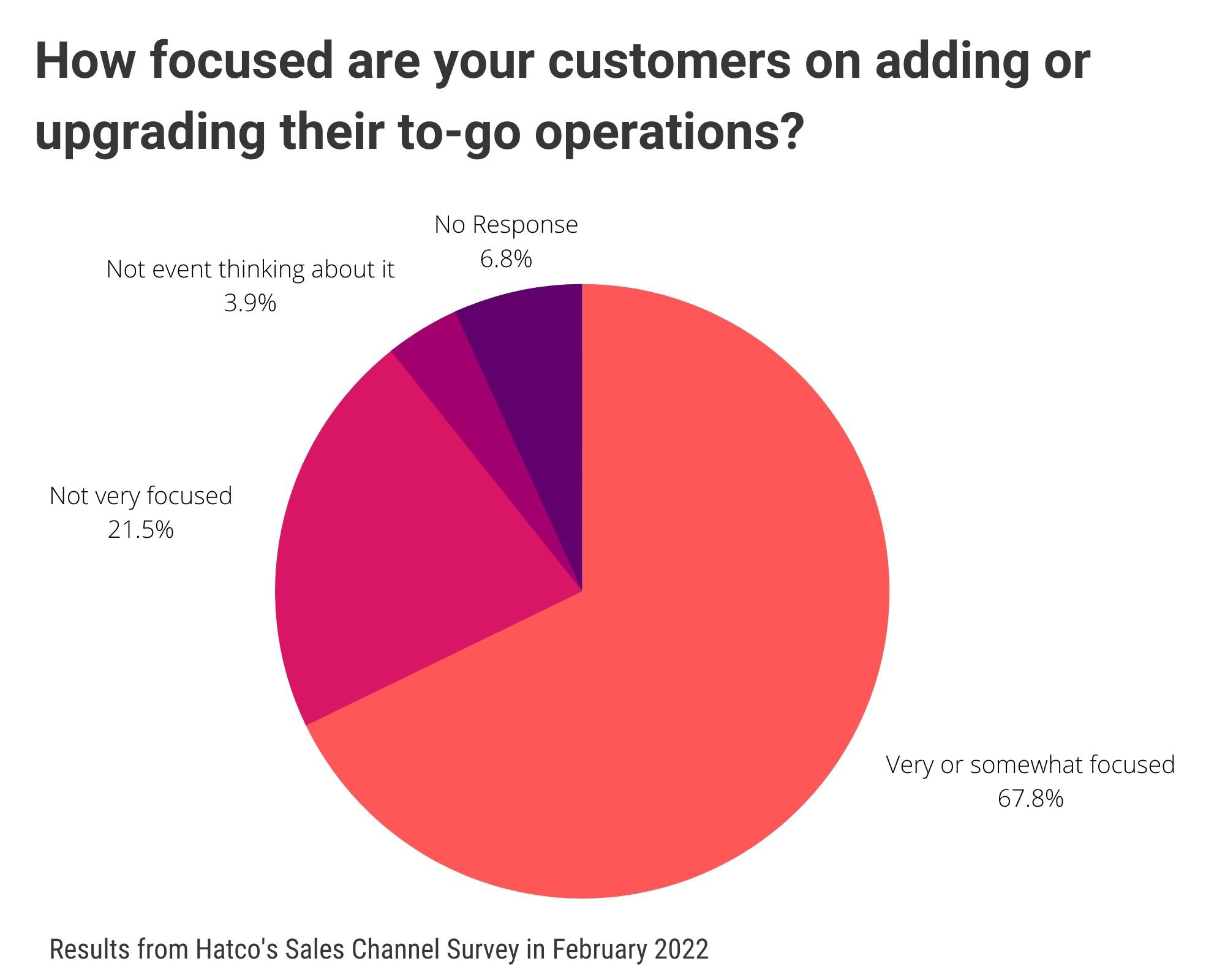

In the latest Hatco Customer Insights Survey, participating Hatco sales representatives and dealers reported that the vast majority of foodservice buyers have their sights set on to-go services. When asked how focused their customers are on adding or upgrading their to-go operations, the majority (67.8%) stated that customers are “very” or “somewhat focused” on it. Just 21.9% of participants said their customers are “not very focused,” and even less (3.9%) said customers weren’t even thinking about to-go offerings. In other words, a whopping 70% of buyers could be looking for equipment solutions to help them up their to-go game — and that’s a pretty solid opportunity!

What are your customers asking about to-go?

It’s clear that the majority of establishments are focused on increasing to-go offerings, but how can it be done successfully? Hatco’s Customer Insights Survey shed some crucial light on the questions buyers are asking. Let’s explore these questions and how the right answers can help your customers push their to-go business to the next level.

1. What types of equipment can be used to facilitate pickup and delivery?

Early on in the pandemic, pickup and delivery foods were often the only meals operators were serving. The quick onset (in some cases overnight) of pickup and delivery forced some operations to use whatever solutions they had on hand for service: shelves, cubbies, carts — almost anything was fair game. As time went on, foodservice establishments got savvier and thoughtfully repurposed unused temperature-controlled equipment as a solution. Some operators even used well covers to convert their deserted buffets into to-go shelves, or created pop-up grab-n-go areas using hot-holding cabinets that were no longer being used for dine-in service.

While the ingenuity should be applauded, the bar for to-go has risen. Self-service, automated equipment is now the peak of today’s to-go goals. Heated lockers, pods, self-serve kiosks and foodservice robots (yes, robots) have features that substantially improve pickup and delivery. For example, locked foodservice pods allow pickup customers and third-party delivery drivers to bypass standing in line and instead easily access their order without waiting for an employee to hand off the goods. The result? Shorter cashier lines, less customer frustrations and relief for overworked staff.

2. Does to-go equipment keep hot foods at the proper temperatures?

Whether cold, hot or ambient, food safety hinges on preparing and holding foods at the proper temperatures. When talking about hot foods, one popular option for keeping food toasty in staff-operated to-go stations are heated shelves. One example is Hatco’s Glo-Ray™ 2-Go Heated Shelves. These units feature individual thermostatically-controlled shelves with a temperature range of up to 200°F (93°C). Created specifically with to-go and delivery in mind, these heated shelves hold food for up to 30 minutes. But what about operations that already have their hands full with dine-in customers (like the situation stated above) or establishments that have limited customer interaction?

Temperature-controlled lockers, insulated pods, or temperature-regulated display cabinets are great solutions. For instance, Hatco’s Flav-R 2-Go® Heated Locker System is preset at 150°F (66°C) with a high-temperature range of up to 180°F (82°C). That way, food is held at just the right temperature, never compromising safety or quality. These locker systems also feature a timer that holds packaged foods for up to 45 minutes, helping operators ensure food quality remains tip-top. Lastly, there’s a lot of versatility with these lockers, as operators can easily turn the heat off for holding ambient friendly foods when needed.

3. How do I ensure customers get the right to-go orders while also keeping food safe from theft and tampering?

This is a popular customer question. Time and temperature are heavy hitters in food safety, but adequate security is also important. Nothing rivals the ick-factor quite like a random stranger rummaging through several orders to find their food. Or, even more frustrating (to both the kitchen and customer) is someone intentionally or unintentionally grabbing food they didn’t order.

As a remedy, locked to-go equipment helps eliminate these situations by ensuring prepared food items make their way to the correct customer without accidental or intentional tampering. Hatco’s Pickup Pod™ do this by sending a QR code to the customer via email or embedded SMS link, allowing the customer to open the locker on their own. Or, the Flav-R 2-Go lockers we mentioned earlier allow customers to simply locate their name on the unit’s illuminated screen, enter their order code and watch as the correct door opens. Within just a few seconds, a tasty meal is ready for its next destination — whether that’s a delivery driver’s car or straight into the customer’s belly.

4. Self-service to-go equipment can be great for labor savings, but my staff are wondering if this kind of automation will impact their job security. How can I calm their concerns?

Serving meals that satisfy customers is the ultimate goal, but every operation knows that the foundation of any successful foodservice establishment is the people who work there. And here’s the deal: Self-serve pickup equipment takes on a huge piece of the sweat and labor behind to-go (there’s no skirting that), but hard-working staff are still needed. Think of to-go equipment as an extra set of hands that enable workers to focus on other, more-pressing tasks. As an illustration, think about order pickup stations and food lockers. These solutions allow kitchen staff to prepare and package menu items, place them in a secure, temperature-regulated or insulated compartment, and not worry about the rest. As a result, peak service times become less stress-filled and more manageable.

5. New equipment is exciting, but our space is already a little snug. What’s the footprint for to-go equipment?

When talking about to-go, space is often a factor. And depending on the operation, more equipment taking up floor space can sound like a real headache. But thankfully, space limitations don’t have to limit customers’ options. There are many to-go equipment solutions available with different-sized footprints.

If space is an issue, a smaller, insulated pickup pod with vertical orientation or a countertop locker unit might be the right move. Or, if space isn’t an issue but keeping up with a high volume of orders is, a floor-mounted locker system could provide buyers with the large holding capacity they need.

But keep in mind, the model type and size typically affect how many lockers are within each unit (equaling the number of orders it can hold). Further, the spaciousness of each cubby depends on the model type as well. But whichever model your customer opts for, there’s no denying that self-serve to-go equipment is always a win for growing pickup operations.

6. Are there specific requirements to keep in mind with self-service to-go equipment?

There’s nothing more disappointing to a buyer than ordering equipment only to find it has specific requirements they weren’t aware of. Give your customers a hand by offering a little equipment-purchasing 101 advice. First off, remind buyers to check how much voltage is available in their location’s building. This will ensure they order a unit that’s rated for the appropriate voltage. And with that, buyers should confirm that their circuit can handle the amp load delivered by the equipment. If a buyer is outside of the US, they should also confirm if 50 or 60 hertz is the norm in their region, and that the equipment they are purchasing is compatible. This is all pretty technical stuff, so check out our blog, Amps, Watts, Volts and Hertz: What They Mean and Why You Need To Know, for more detailed information.

In addition to electrical requirements, some automated pickup equipment (such as the Hatco Pickup Pod) require monthly software-as-a-service (SaaS) fees. While these fees may feel like “just another cost” to some customers, there’s actually a whole slew of benefits to going with SaaS-powered foodservice equipment, including labor savings (the vendor handles the software updates and enhancements), continuous access to the most recent version of the software, system integration opportunities, internet of things (IoT) functionality, advanced data analytics, and more.

7. How easily can automated to-go equipment integrate with my POS system?

Not all to-go equipment offers integrations, but one of the benefits of internet-connected equipment is that it lends itself to integrations with other systems, such as an operator’s point of sale (POS) solution. Hatco’s Pickup Pod is one example. This unit seamlessly integrates with POS systems Toast and Square, allowing those systems to automatically populate the diner’s information directly into the pickup pod. There’s no manual entry from the operator, saving time and labor (which of course equals money).

8. Who should I call if something goes wrong with the to-go equipment?

It’s never fun when equipment breaks down or malfunctions, but the first thing customers should do when it happens is check if the equipment is under warranty. If the issue is covered, customers should contact the manufacturer and carefully follow the instructions for getting the unit serviced or replaced. But warranties don’t last forever. If maintenance is needed after a warranty expires, direct customers toward a technician or company that specializes in restaurant equipment service. Thankfully, Hatco has a network of qualified technicians and companies that we recommend. Going this route is a wise move and helps ensure the service company is vetted and capable of quality work.

9. I know the supply chain is challenging, what is the lead time for to-go equipment?

It’s no secret that supply chain disruptions are in full force, creating challenges with just about everything — foodservice equipment included. However, there’s no magic formula for lead time and it typically varies depending on the product. For specific Hatco lead time information, the best bet is to have the customer reach back out to you (the salesperson) or contact our customer service team.

If lead times are longer than a customer can wait, offer up another equipment solution that will still meet their operation’s needs, but ship faster. For example, are there suitable replacements that are part of Hatco’s Quick-Ship program? This program makes many of the most popular Hatco products available for immediate shipment and could be an excellent solution for buyers with time-sensitive equipment needs.

10. How can I show a positive ROI with purchasing new to-go equipment?

Finding the return on investment (ROI) for equipment involves calculations based on the amount spent and the years it takes to pay the unit off. But other factors also come into play, such as fewer service calls for new equipment and increased functionality. For example, self-service to-go equipment can lessen labor costs through automation. While at the same time, a quick, convenient, secure and safe pickup solution encourages increased to-go sales. All of these things can contribute toward a positive ROI. Help support your customers by encouraging them to carefully weigh all the factors of purchasing (or leasing) a new to-go solution, so they can make the best financial investment for their business.

Get on board.

With a vast amount of commercial kitchen equipment moving more toward automation, it’s pretty clear that self-serve pickup equipment is a big part of the future of to-go. And as an expert in the foodservice equipment field, you know that understanding the ins and outs of available products helps to better serve your customers. Stay up to speed by learning more about all the automated to-go equipment Hatco has to offer. For starters, be sure to check out our latest to-go resource.